Structural design

The structural design of low-temperature pressure vessels should consider sufficient flexibility, and the main requirements are as follows:

① The structure should be as simple as possible to reduce the constraints between welded components;

② Structural design should avoid generating excessive temperature gradients;

③ Sharp changes in the cross-section should be avoided as much as possible to reduce local stress concentration. The inner end of the plug-in nozzle should be polished into a rounded corner to ensure a smooth transition;

④ The connection welds of attachments should not be discontinuous or spot welded;

⑤ The saddle, manifold lug, support leg (excluding spherical tanks) or skirt of the container should be equipped with a pad or connecting plate to avoid direct welding with the container shell. The pad or connecting plate should be considered based on low-temperature materials;

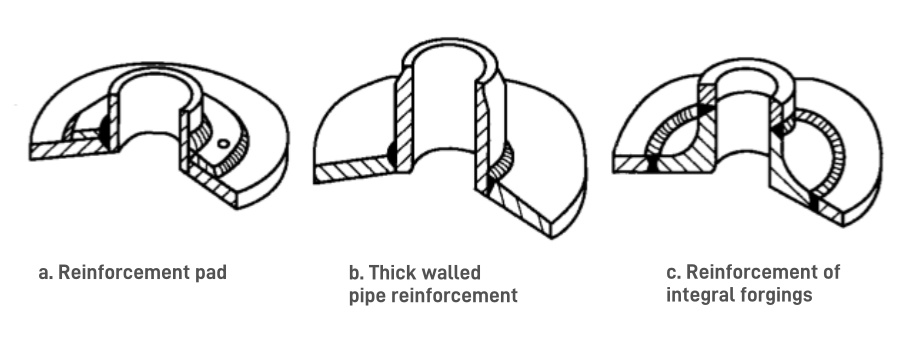

⑥ The reinforcement of takeover should be carried out as much as possible using integral reinforcement or thick walled pipe reinforcement. If reinforcement pads are used, the weld seam should have a smooth transition;

⑦ For containers that cannot undergo overall heat treatment, if the welded components need to be stress relieved, consideration should be given to the individual heat treatment of the components.

Opening for connecting pipes

The opening of the connecting pipe for low-temperature pressure vessels should be avoided as much as possible from the main weld seam and its surrounding area. If it is necessary to open a hole in the weld seam area, it should comply with the requirements of relevant standards.

The connecting pipes on low-temperature pressure vessels should meet the following requirements:

① The wall thickness of the section welded to the shell should not be less than 5mm. For pipes with a diameter of DN ≤ 50mm, thick walled pipes should be used, and the extended part should be made of ordinary seamless steel pipes with a wall thickness;

② Bends made by simmering or pressing should be used at bends, and straight pipe welding (shrimp elbows) should not be used;

③ For plug-in nozzles, the sharp corners of the inner pipe end of the shell wall need to be turned or polished to a rounded corner of R ≥ 3mm;

④ The longitudinal weld seam and the circumferential weld seam between pipe sections when using coiled pipes for takeover should adopt a fully welded structure;

⑤ For hazardous media that are extremely flammable or highly toxic, or when the pressure is ≥ 1.6 MPa, The T-shaped joint should adopt a seamless extruded tee or a structure with thickened pipe openings and welding.

Flange

Butt welded flanges should be used for flanges that meet the following conditions:

① Container flanges with a design pressure of ≥ 1.60MPa and containing highly flammable or toxic media, or connecting flanges with significant external loads;

② Vessel flanges and connecting flanges with a design pressure of ≥ 2.50MPa.

Butt welded flanges should be produced using seamless forging or rolling processes, and it is not allowed to use thick steel plates for cutting; It is allowed to use structural steel or steel plates bent or welded, but post weld heat treatment is required. If steel plate bending is used, the steel plate should be cut into strips along the rolling direction. When bending, the surface of the steel plate should be parallel to the centerline of the flange, and ultrasonic testing must also be performed on the steel plate.

Fasteners

The main requirements are as follows:

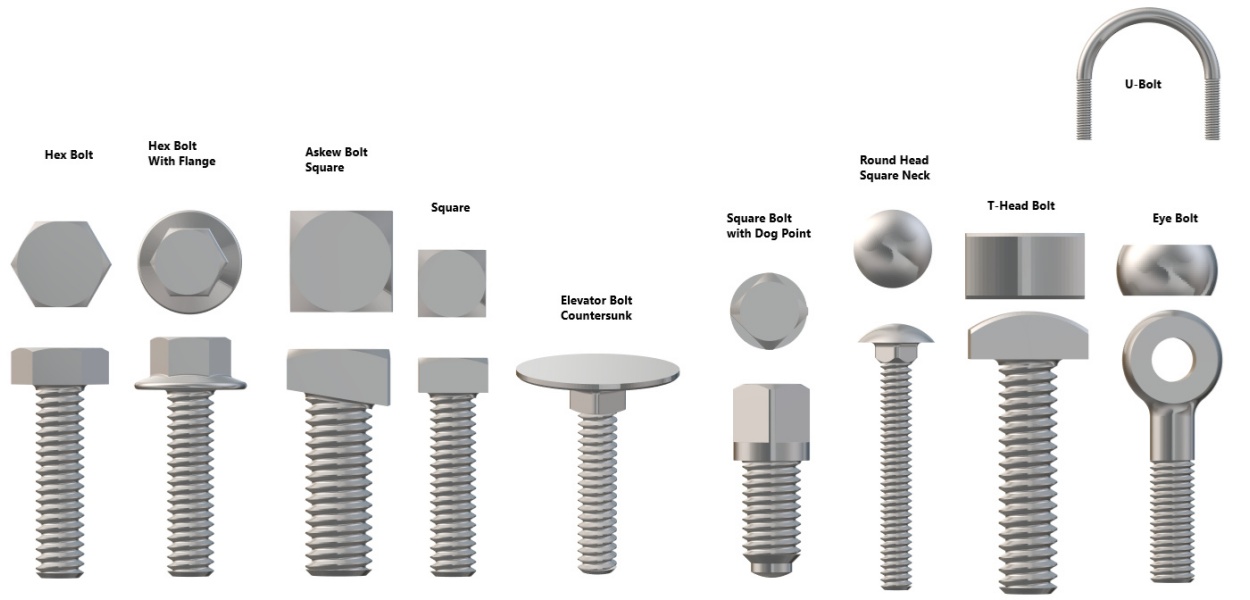

①The bolts, stud, and other fasteners used for flanges of low-temperature pressure vessels shall not use general ferrite commodity fasteners matched with nuts. General commodity nuts are allowed to be used, but the operating temperature should not be lower than -40 ℃;

② Recommend using elastic bolts and studs with a core diameter not exceeding 0.9 times the thread root diameter and no thread in the middle;

③ For ferritic steel vessels with a design temperature not lower than -100 ℃, ferritic steel fasteners (studs, bolts, nuts, washers) should be used. For austenitic steel vessels with a design temperature lower than -100 ℃, austenitic steel fasteners should be used;

④ A2 grade austenitic steel commercial fasteners in accordance with GB 3098.6 "Mechanical Properties of Fasteners - Stainless Steel Bolts, Screws, and Studs" can be used in low-temperature pressure vessels not lower than -196 ℃;

⑤ For stress reducing conditions, when the adjusted impact test temperature is equal to or higher than -20 ℃, general ferrite commodity fasteners can be used.

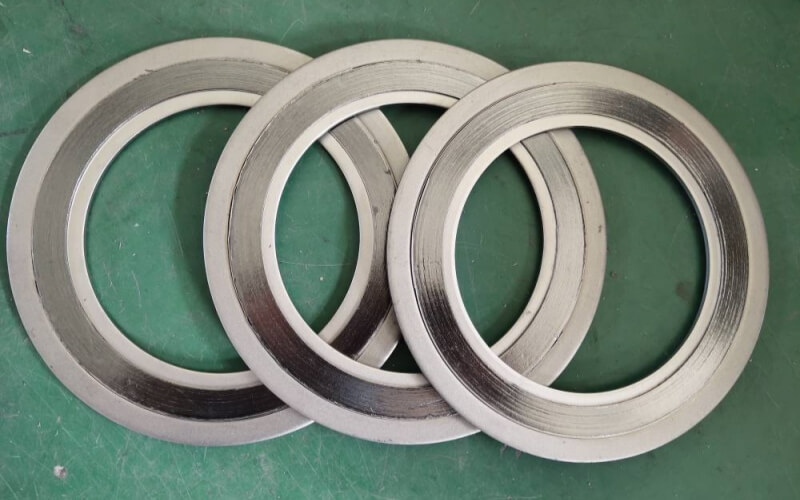

Sealing gasket

The commonly used sealing gaskets for low-temperature pressure vessels include gaskets made of metal materials (including semi metal gaskets) and non-metallic materials. The conditions and requirements are as follows.

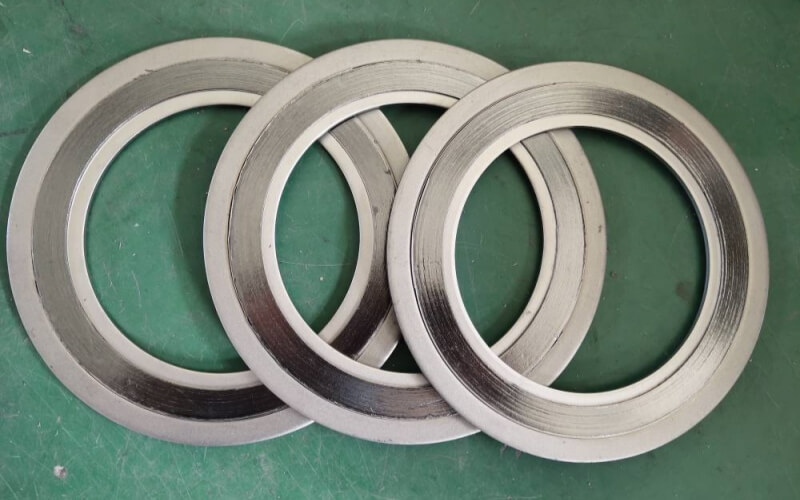

① Metal materials used for sealing gaskets with temperatures below -40 ℃ should be austenitic stainless steel, copper, aluminum, and other metal materials that have no obvious transformation characteristics at low temperatures, including the metal strip of spiral wound gaskets, the shell of metal wrapped gaskets, and hollow or solid metal gaskets.

② Non metallic sealing gaskets should be made of materials that exhibit good elasticity at low temperatures, such as asbestos, flexible (expanded) graphite, polytetrafluoroethylene, etc. The usage conditions are as follows:

The flange sealing gasket with a temperature not lower than -40 ℃ and a pressure not higher than 2.5MPa is allowed to use high-quality asbestos rubber sheets, asbestos free rubber sheets, flexible (expanded) graphite sheets, polyethylene sheets, etc; High quality asbestos rubber sheets soaked in paraffin are allowed for flange gaskets with a temperature not lower than -120 ℃ and a pressure not higher than 1.6MPa.

Welding

The main requirements are as follows.

① For A B. All C-class welds should adopt a fully penetrated structure. For Class D welds, except for the welding between the flange and the container wall, the welding between small diameter nozzles (DN ≤ 50mm) and thicker heads or cover plates, and the connection between pipe joints with internal threads and the container wall, which can be in accordance with the relevant provisions of HG 20582, full penetration structures should also be used.

② Before welding low-temperature pressure vessels, welding process evaluation should be carried out, with a focus on the low-temperature Charpy (V-notch) impact test of the weld seam and heat affected zone. The qualification index should be determined according to the requirements of the base material and should not be lower than the performance of the base material.

③ During the welding process, the welding wire energy should be strictly controlled within the range specified in the process evaluation. It is advisable to choose a smaller welding wire energy for multi pass welding.

④ The butt weld must be fully welded, and the excess height of the weld should be minimized as much as possible, not exceeding 10% of the thickness of the welded part, and not exceeding 3mm. The fillet weld should be smooth and not allowed to protrude outward. The surface of the weld seam should not have defects such as cracks, pores, and undercuts, and there should be no sharp shape changes. All transitions should be smooth.

⑤ Arc ignition is not allowed in non welding areas. Arc ignition should be carried out using arc plates or within the groove.

⑥ Welding attachments, fixtures, braces, etc. must use the same welding materials and welding processes as the shell material, and be welded by qualified formal welders. The length of the weld bead must not be less than 50mm.

⑦ Surface damage to containers caused by mechanical processing, welding, or assembly, such as scratches, welding scars, arc pits, and other defects, should be repaired and ground. The wall thickness after grinding shall not be less than the calculated thickness of the container plus corrosion allowance, and the grinding depth shall not exceed 5% of the nominal thickness of the container and shall not exceed 2mm.

⑧ Discontinuous or spot welded joints are not allowed.

Wuxi Changrun has provided high-quality tube sheets, nozzles, flanges, and customized forgings for heat exchangers, boilers, pressure vessels, etc. to many well-known petrochemical enterprises at home and abroad. Our customers include PetroChina, Sinopec, Chevron, Bayer, Shell, BASF, etc. Send your drawings to sales@wuxichangrun.com We will provide you with the best quotation and the highest quality products.