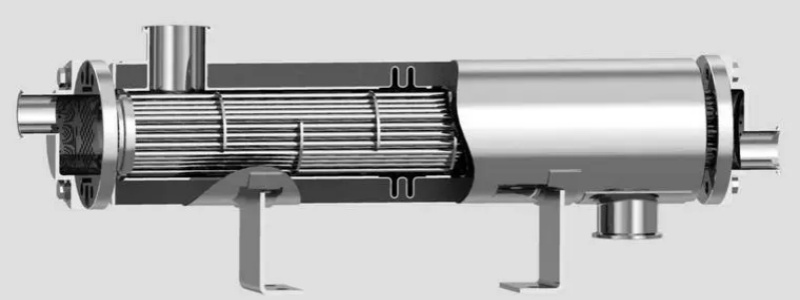

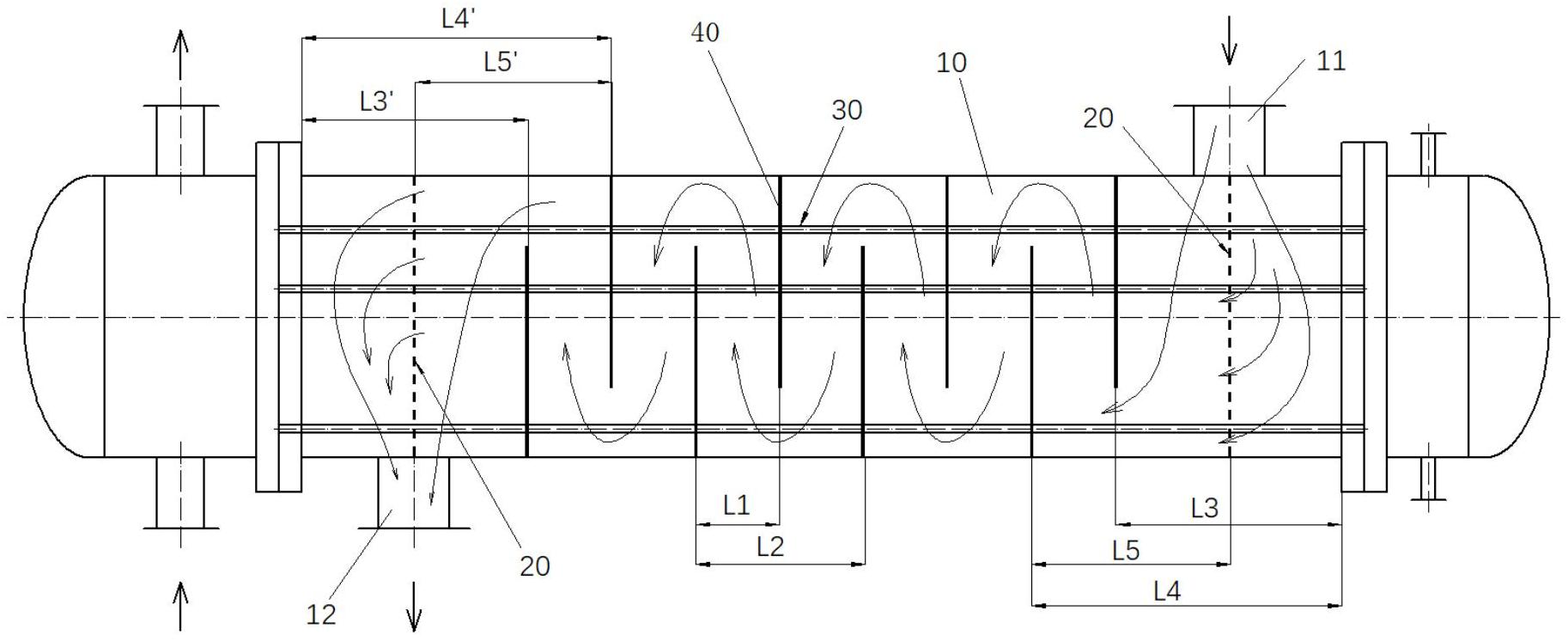

A double tube sheet heat exchanger is a heat exchanger with two tube sheets with a certain gap at one end of the heat exchanger.

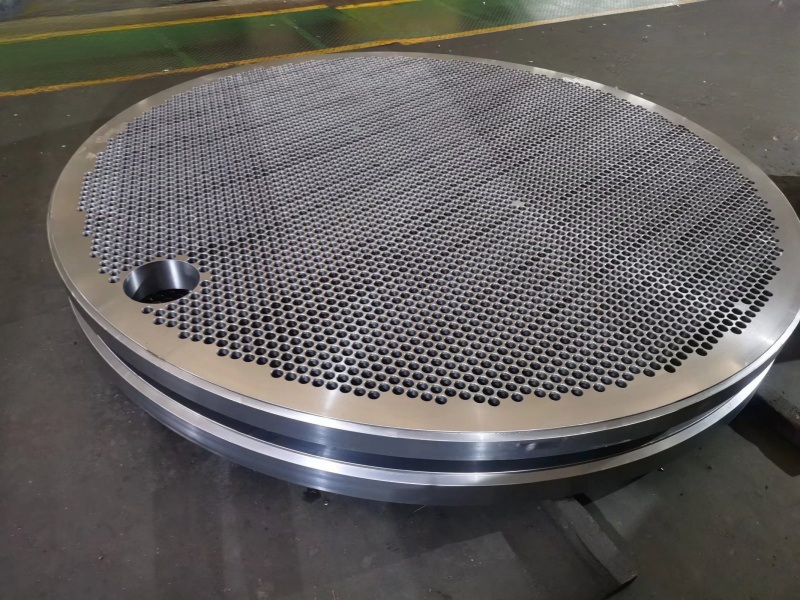

At the end of the heat exchange tube, there is a tube sheet called the outer tube sheet, also known as the tube side tube sheet, which serves as an equipment flange and is connected to the heat exchange tube and channel flange. There is also a tube sheet located closer to the end of the heat exchange tube, called the inner tube sheet, which is the shell side tube sheet, connected to the heat exchange tube and the shell side.

There is a certain distance between the outer and inner tube sheets, and this space can be separated from the outside by a skirt segment, forming a pressure free isolation chamber; It can also be an open structure.

Application of double tube sheet heat exchanger

In practical operation, double tube sheet heat exchangers are generally used in the following two situations:

1.One is to absolutely prevent the mixing of media between the shell and tube sides, for example, in heat exchangers where water flows through the shell side or chlorine or chloride flows through the tube side. If the water in the shell side comes into contact with chlorine or chlorides in the tube side, it will produce highly corrosive hydrochloric acid or hypochlorous acid, which will cause serious corrosion to the material of the tube side.

Adopting a double tube sheet structure can effectively prevent the mixing of two materials, thereby preventing the occurrence of the above-mentioned accidents.

2.Another scenario is when there is a large pressure difference between the medium on the tube and shell side. In this case, a medium is usually added to the cavity between the inner and outer tube sheets to reduce the pressure difference between the medium on the tube and shell side.

When the mixing of heat exchanger tube side and shell side media is strictly prohibited in the following situations, a double tube sheet structure is often used:

① When the two media of the tube side and shell side are mixed, it will cause serious corrosion;

② The infiltration of extremely or highly hazardous media on one side into the other can cause serious consequences;

③ When the medium on the tube side and the medium on the shell side are mixed, the two media will cause combustion or explosion;

④ When one medium mixes with another, it causes catalyst poisoning;

⑤ Mixing the tube side and shell side media can cause polymerization or the formation of resin like substances;

⑥ The mixing of the tube side and shell side media can cause the termination or restriction of chemical reactions;

⑦ The mixing of tube side and shell side media can cause product contamination or a decrease in product quality.

Comparison of double tube sheet and single tube sheet heat exchanger structures

The double tube sheet heat exchanger adopts a fixed tube sheet structure, and the tube bundle cannot be extracted for cleaning. The single tube sheet heat exchanger can adopt a variety of structural types, and the tube bundle can be extracted for cleaning. For double tube sheet heat exchangers with large temperature differences, corrugated expansion joints can be installed on the simplified structure; for single tube sheet heat exchangers, in addition to installing corrugated expansion joints on the simplified structure, floating heads or U-shaped tubes are often used to compensate.

There are two design concepts for double tube sheet heat exchangers: one believes that double tube sheet heat exchangers are used to absolutely prevent the mixing of media between the tube and shell sides. A drainage and backflow valve is designed to be installed on the cavity between the inner and outer tube sheets for daily observation and discharge in case of leakage of the inner tube plate, so that the medium on the tube and shell side is effectively isolated by the inner and outer layer tube sheets. This is the main purpose of using a double tube sheet structure.

Another view is that double tube sheet heat exchangers can be used in situations where the pressure difference between the tube and shell side media is large. A medium is designed to be added to the cavity between the inner and outer tube sheets to reduce the pressure difference between the tube and shell side media. This is similar to a typical single tube sheet heat exchanger, and it cannot be absolutely guaranteed that there will be no leakage from the pipe opening on the outer tube sheet.

Comparison of the use of double tube sheet and single tube sheet heat exchangers

Single tube sheet heat exchangers are the most common. In addition to frequent leakage of gaskets, bolts, flanges, and joint seals during use, there may also be leakage of pipe openings on the tube sheet, as well as welding cracks. Most of the pipe mouth leaks on the single tube sheet heat exchanger occur at the welding arc end. During welding, the gas was not completely discharged and there were sand holes.

The double tube sheet heat exchanger has inner and outer double tube sheets, and if there is a leakage at the inner tube sheet and tube ends, there is also an outer tube sheet protection.

Welding cracks in single tube plate heat exchangers often occur at the joint between the flange and the shell of the heat exchanger. The main reason for the problem here is that the stress at the junction between the flange and the cylinder is high; The second is the sudden change in geometric size and shape, which makes it easy to bury defects.

The joint between the simplified large flange and the cylinder of the double tube sheet heat exchanger is located on the outer edge of the cavity formed between the inner and outer tube sheets, and there is no medium in the cavity or the medium pressure is very low. The stress condition is better than that of a single tube sheet heat exchanger.

In addition, the pressure test of the double tube plate heat exchanger needs to be conducted 4 times (tube side, shell side between two inner tube plates, and cavity between inner and outer tube plates on both sides), while the pressure test of the single tube plate heat exchanger needs to be conducted 2-3 times (tube side, shell side or tube side, shell side, and small float).

Comparison of Manufacturing Double Tube Sheet and Single Tube Sheet Heat Exchangers

① Costs

Compared with a single tube sheet heat exchanger, a double tube sheet heat exchanger adds two outer tube sheets, a cavity between the two inner and outer tube sheets, and heat exchange tubes in the cavity. At present, the price of double tube sheet heat exchangers ordered domestically is about 10-20% higher than that of single tube sheet heat exchangers ordered.

If the double tube sheet structure and single tube sheet structure are used as heat exchangers respectively, the weight of the double tube sheet is increased by 10% to 20% compared to the single tube sheet, and the cost is increased by 25% to 37%. Therefore, more attention should be paid to the manufacturing quality of double tube sheet heat exchangers, so that more money can be spent to achieve good results.

② Expansion joint

Usually, there are roughly four forms of connection between heat exchange tubes and tube sheets, namely strength welding (commonly argon arc welding), strength expansion, strength welding+adhesive expansion, and strength expansion+sealing welding. The differences are mainly reflected in whether the tube holes are slotted, the welding groove, and the length of the tube extension. Expansion joints can be divided into non-uniform expansion joints (mechanical ball expansion joints), uniform expansion joints (hydraulic expansion joints, liquid bag expansion joints, rubber expansion joints, explosive expansion joints, etc.).

The design of the double tube sheet heat exchanger requires strength welding and strength expansion, and it is recommended to use the hydraulic expansion method. The general design requirement for single tube sheet heat exchangers is to use strength welding and adhesive expansion, and mechanical or manual expansion can be used.

At present, most domestic manufacturers do not have hydraulic expansion equipment. Even if they do, due to the high cost of purchasing hydraulic expansion heads and high losses (with an average expansion of over 100 pipe openings, a new hydraulic expansion head is required). Hydraulic expansion head is disposable and cannot be repaired.

Therefore, hydraulic expansion tube method is rarely used to manufacture heat exchangers.

Wuxi Changrun has provided high-quality tube sheets, nozzles, flanges, and customized forgings for heat exchangers, boilers, pressure vessels, etc. to many well-known petrochemical enterprises at home and abroad. Our customers include PetroChina, Sinopec, Chevron, Bayer, Shell, BASF, etc. Send your drawings to sales@wuxichangrun.com We will provide you with the best quotation and the highest quality products.