Discover the Benefits of Outside Curve Brushes

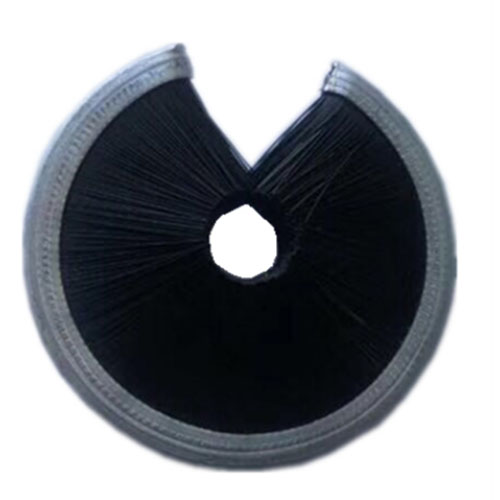

In the realm of industrial brushes, outside curve brushes stand out as a specialized tool designed for unique applications that require precision and efficiency. These brushes are engineered to tackle tasks that involve curved surfaces, making them indispensable in various industries.

Key Features of Outside Curve Brushes

Ergonomic Design: The curved shape of these brushes allows for better contact with rounded surfaces, ensuring thorough cleaning and finishing. This ergonomic design minimizes user fatigue while maximizing effectiveness.

Versatile Bristle Options: Available in various bristle materials—such as nylon, steel, and natural fibers—outside curve brushes can be customized to suit specific cleaning or polishing needs across different materials.

High Durability: Crafted to withstand rigorous industrial environments, these brushes are built to last, offering consistent performance even under heavy use.

Efficient Cleaning: The design of outside curve brushes enables them to effectively clean hard-to-reach areas and intricate contours, making them ideal for complex machinery and components.

Applications of Outside Curve Brushes

Automotive Industry: Used for cleaning and finishing curved components, these brushes ensure that every part meets strict quality standards, enhancing overall product reliability.

Aerospace Manufacturing: In aerospace applications, where precision is critical, outside curve brushes help maintain the integrity of complex surfaces and reduce the risk of imperfections.

Metal Fabrication: Ideal for deburring and polishing, these brushes are essential in the metalworking industry, ensuring smooth finishes on curved edges and surfaces.

Mold and Die Cleaning: Effective for cleaning molds and dies, the curved design allows for thorough cleaning of intricate details, extending the lifespan of these critical tools.

Why Choose Outside Curve Brushes?

Choosing outside curve brushes means investing in a tool that enhances efficiency and effectiveness in specialized cleaning and finishing tasks. Their unique design and robust construction make them the perfect choice for industries that demand precision and reliability.

By integrating these brushes into your processes, you can ensure that your products maintain the highest quality standards while streamlining operations.